#automated liquid handling system

Explore tagged Tumblr posts

Text

Evaluating the Return on Investment (ROI) of Automated Liquid Handling Systems

In today’s fast-paced scientific research and diagnostic environments, efficiency, accuracy, and reliability are essential for laboratories aiming to meet increasing demands. One of the most impactful innovations in laboratory automation is the automated liquid handling system. These systems, designed to perform a variety of liquid dispensing tasks with precision and speed, have become indispensable in modern labs. However, like any significant capital investment, organizations must evaluate the return on investment (ROI) before integrating these systems into their workflows.

In this blog, we’ll break down the key factors to consider when assessing the ROI of automated liquid handling systems, covering how these systems influence cost savings, productivity, and long-term value for labs.

1. Direct Cost Savings

One of the most apparent aspects of ROI for automated liquid handling systems is the reduction in direct costs associated with manual pipetting and liquid handling processes. Automated systems help lower costs in several ways:

Reduced Reagent Waste: Automated systems can dispense precise volumes, minimizing reagent wastage due to human error or variability. Over time, this can result in significant savings, especially for costly reagents.

Lower Labor Costs: Replacing or supplementing manual labor with automation reduces the need for skilled personnel to spend time on repetitive tasks. This frees up technicians and scientists to focus on higher-value activities.

Fewer Errors and Reworks: Human errors in liquid handling can lead to failed experiments or inaccurate data, resulting in the need for reworks. Automated systems improve accuracy, reducing the need for costly reruns of assays or experiments.

2. Increased Productivity

Automated liquid handling systems are capable of working faster than humans, and can operate for long hours, even continuously if needed. Here’s how automation boosts productivity:

Time Efficiency: Tasks that would typically take hours for a human technician can be performed in a fraction of the time by an automated system. This significantly increases throughput, especially in high-demand settings like drug discovery or genomic testing labs.

24/7 Operation: Automated systems can work around the clock, which is a critical advantage for labs with high sample volumes. Overnight or weekend operations can further enhance output without requiring additional human resources.

Batch Processing: These systems are capable of handling multiple plates or samples simultaneously, allowing for large-scale experiments or tests to be completed much faster than manual processes.

3. Improved Accuracy and Data Quality

One of the primary advantages of using automated liquid handling systems is the high precision they offer. Human variability is a challenge in manual pipetting, which can lead to errors in volumes, dilution factors, or sample contamination. Automated systems offer:

Consistent Precision: Automated systems are designed to deliver precise volumes every time, reducing errors associated with manual liquid handling.

Reproducibility: Consistency in experimental processes leads to more reliable and reproducible results, which is critical in regulated environments or when scaling up experiments.

Reduced Contamination Risk: Many automated systems are designed with features that minimize contamination risk, further improving the quality of the results.

4. Long-Term Value and Scalability

While the initial investment in automated liquid handling systems can be significant, the long-term value they provide often justifies the cost. As laboratories grow and scale their operations, automated systems can continue to meet rising demands without the need for additional staff. Key points to consider include:

Scalability: Automated systems can be programmed to handle varying volumes and tasks, making them adaptable to changing workloads. As your lab’s requirements increase, the system can often scale without the need for additional units.

Flexible Applications: Many automated liquid handling equipment are versatile, capable of being used for multiple applications such as PCR setup, ELISA, or drug screening. This adaptability further enhances their long-term value.

5. Hidden Costs to Consider

While evaluating ROI, it's essential to account for some potential hidden costs, including:

Maintenance and Servicing: Like any machine, automated systems require regular maintenance to keep them running smoothly. The costs of service contracts, repairs, and replacement parts should be factored into the ROI analysis.

Training Costs: Training staff to operate and troubleshoot the automated system is necessary and can involve a time and financial investment. However, once trained, operators can improve system efficiency and minimize downtime.

Initial Downtime During Implementation: During the initial setup phase, there may be some downtime as the system is integrated into workflows, and staff become familiar with its operation. This temporary dip in productivity should be balanced against long-term gains.

6. Qualitative Benefits

Beyond the quantitative ROI, there are qualitative benefits of automated liquid handling systems that contribute to the overall success of a lab:

Employee Satisfaction: By automating tedious and repetitive tasks, lab staff can focus on more intellectually stimulating work. This can lead to improved job satisfaction, retention rates, and a better overall work environment.

Enhanced Lab Competitiveness: Labs that adopt automation are often more competitive, attracting more projects, clients, or funding due to their ability to handle higher volumes with greater accuracy and speed.

Conclusion: Making an Informed Decision

Evaluating the ROI of an automated liquid handling system involves looking at both direct and indirect cost savings, productivity gains, and the long-term value it brings to the laboratory. Although the upfront investment may seem steep, the substantial savings in labor, increased throughput, improved data quality, and scalability typically provide an attractive ROI in the medium to long term.

For laboratories seeking to stay ahead of the curve, especially those working in high-throughput or regulated environments, investing in automated liquid handling technology is not just about increasing efficiency; it's about staying competitive and maintaining accuracy in an ever-evolving scientific landscape. By weighing both the tangible and intangible benefits, labs can make an informed decision about whether an automated liquid handling system is the right investment for their specific needs.

0 notes

Text

Reliable Liquid Handling Systems in Haryana for Industrial Efficiency

When it comes to industrial manufacturing and chemical processing, the need for reliable liquid handling systems in Haryana has become essential. These systems are designed to ensure safe, efficient, and accurate transfer of liquids in various sectors such as food processing, pharmaceuticals, sugar production, and beverage industries. Haryana, being an emerging hub of industrial development, has seen a rapid rise in demand for high-performance liquid transfer solutions.

Liquid handling systems in Haryana are not just limited to pumps and pipes. They include a wide range of tools like dosing systems, transfer units, metering pumps, storage tanks, and valves. These components together help in managing liquids precisely, reducing waste, and improving production workflows. For companies in Haryana that deal with bulk liquid materials, such systems are not just a choice—they’re a necessity for safe and efficient operations.

Many industries in locations like Faridabad, Panipat, Sonipat, and Bahadurgarh are now investing in customized liquid handling solutions to meet their process-specific needs. These cities are home to several food processing plants, chemical factories, and pharmaceutical units, making the region one of the most demanding zones for liquid handling systems in Haryana.

One of the key advantages of modern liquid handling systems is their automation capability. Automated liquid transfer reduces human error, minimizes exposure to hazardous chemicals, and ensures consistent product quality. In Haryana, this automation is helping local manufacturers comply with national and international standards, leading to smoother audits and increased exports.

Moreover, liquid handling technology is evolving to match the growing demand for eco-friendly and low-maintenance operations. In Haryana’s industrial belts, many manufacturers are now using energy-efficient motors, stainless steel contact parts, and corrosion-resistant components to improve the lifecycle and performance of their liquid systems. This shift not only helps in saving long-term operational costs but also promotes sustainable manufacturing practices.

Companies providing liquid handling systems in Haryana often offer installation, maintenance, and on-site training services. This makes it easier for industries to adopt the latest systems without the challenge of handling everything on their own. These service providers play a crucial role in supporting both small-scale units and large factories in places like Karnal, Hisar, Rohtak, and Ambala.

When choosing the right liquid handling setup, factors like type of liquid, flow rate, pressure requirements, and safety standards are carefully considered. Most systems are custom-built to meet the specific requirements of a plant. From high-viscosity fluids to aggressive chemicals, liquid handling systems in Haryana are now capable of handling it all with precision and reliability.

To sum it up, the demand for liquid handling systems in Haryana is growing rapidly across industries due to the state’s expanding industrial infrastructure and increased focus on automation. Businesses looking to improve their production quality and safety must consider investing in these systems. Whether it’s for food-grade liquids, chemicals, or water treatment, the right liquid handling solution can make a significant impact on productivity and operational efficiency.

1 note

·

View note

Text

Automated Liquid Handling Systems Market Expected To Grow Substantially Due To Efficiency And Standardization

Automated liquid handling systems are robotic systems intended to handle liquids efficiently and precisely for various life sciences applications like drug discovery and biotechnology research. They provide customized solutions for all volumes of liquid transfers by automating manual processes like pipetting, diluting, aliquoting and mixing of fluids. Automated platforms help standardize liquid processing steps to reduce errors, save time and eliminate repetitive tasks while improving productivity. The global automated liquid handling systems market is estimated to be valued at US$ 5.34 Bn in 2024 and is expected to exhibit a CAGR of 4.7% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: One of the key drivers for the growth of the automated liquid handling systems market is increasing efficiency and standardization of processes. Automated platforms offer high-throughput screening which has become indispensable for drug discovery research. They allow simultaneous processing of a large number of samples with exact precision and consistency, reducing manual repetition. This significantly enhances the workflow and lets researchers focus on more productive tasks. The other major growth driver is the ability of automated systems to minimize human errors during liquid transfer procedures. Manual processes are prone to introduction of contamination or inaccurate dispensing of volumes which automated robotic systems eliminate completely. Standard operating procedures can be programmed to be followed throughout, improving reproducibility and reliability of experiments. The above mentioned advantages of efficiency, precision and error-free handling are expected to continue driving demand over the forecast period. SWOT Analysis Strength: Automated liquid handling systems enable efficient laboratory workflow and consistent results through automation. The systems minimize potential errors through digitized protocols and liquid transfers. Their ability to quickly process high volumes of samples boosts productivity. Weakness: The high initial costs of automated liquid handling systems pose a challenge for small and medium scale laboratories with limited budgets. Additional operating costs are incurred for maintenance, calibration and consumables. Opportunity: Growth in biopharmaceutical and diagnostics industries is driving increased R&D activities and clinical testing volumes. This is creating demand for automation solutions to improve efficiency. Expanding applications in genomics and proteomics also present opportunities. Threats: Increased adoption of refurbished or used automated systems can affect sales of new systems. Stringent regulatory approval procedures and certification requirements increase compliance costs for manufacturers. Key Takeaways The global automated liquid handling systems market growth is expected to witness high growth over the forecast period of 2024 to 2031. The market size is projected to increase from US$ 5.34 Mn in 2024 to over US$ 8.1 Mn by 2031, registering a CAGR of 4.7%. Regional analysis North America currently dominates the global market owing to extensive R&D spending and a large base of pharmaceutical and biotechnology companies. Europe and Asia Pacific are expected to be the fastest growing regional markets. Expanding biomedical research infrastructure and growing diagnostics industry in countries like China and India offer lucrative opportunities for market players in Asia Pacific. Key players Key players operating in the automated liquid handling systems market are BHP Group, Jinduicheng Molybdenum, American CuMo Mining, Thompson Creek Metals, Moly Metal LLP, ENF Ltd., Compania Minera Dona Ines De Collahuasi SCM, and Freeport McMoran.

Get more insights on this topic: https://www.newsstatix.com/automated-liquid-handling-systems-market-industry-insights-trends-automated-liquid-handling-systems-market/

Explore more information on this topic, Please visit: https://whotimes.com/beyond-borders-exploring-the-allure-and-impact-of-mice-events-across-the-united-states/

#Automated Liquid Handling Systems#Automated Liquid Handling Systems Market#Automated Liquid Handling Systems Market size#Automated Liquid Handling Systems Market share#Automated Liquid Handling Systems Market analysis

0 notes

Text

Looking for Automated Liquid Handling Systems in Canada?

Retisoft Inc - Your Solution for automated liquid handling systems in Canada. Discover their cutting-edge technology that simplifies and accelerates liquid handling tasks. From precise pipetting to sample preparation, their advanced systems ensure accuracy and efficiency in your lab. Visit the website for more info.

0 notes

Text

STON.fi x Wisdomise: A New Era of Smart DeFi Trading

The decentralized finance (DeFi) landscape is rapidly evolving, and staying ahead requires innovation, efficiency, and accessibility. STON.fi, the leading decentralized exchange (DEX) on The Open Network (TON), continues to push boundaries, and the latest integration with Wisdomise is another leap forward.

This partnership redefines how traders interact with DeFi, bringing automation, AI-powered insights, and seamless liquidity access into one powerful ecosystem.

Unlocking a Smarter Trading Experience

For many traders, the biggest challenge is timing the market. Buying too early or too late, failing to set stop losses, or missing key trends can significantly impact profits. The STON.fi x Wisdomise integration eliminates this burden, making trading smarter, automated, and more precise.

With this integration, traders now have access to:

AI-powered automation – No more manually monitoring the market 24/7. The system executes trades based on data-driven insights.

Multi-position strategies – Trade multiple assets at once, diversifying risk and maximizing opportunities.

Advanced risk management – Take Profit and Stop Loss features help protect capital while optimizing gains.

Direct access to STON.fi liquidity – Trade seamlessly within Wisdomise without additional complexities.

This means traders can now focus on strategy, while the AI handles execution, risk management, and market tracking.

Wisdomise Auto Trader Launch Tournament – $10,000 in Prizes!

To celebrate this game-changing integration, Wisdomise is hosting an Auto Trader Launch Tournament with a $10,000 prize pool.

Traders who use the platform and generate the highest trading volume will secure rewards, including USDt payouts and Wisdomise Pro+ subscriptions.

For those looking to test their trading strategies while earning extra rewards, this is a huge opportunity.

STON.fi’s Dominance in the TON Ecosystem

This integration is another milestone in STON.fi’s unmatched growth as the leading DEX on TON. The numbers tell the story:

$5+ billion in total trading volume—the highest of any DEX on TON.

4 million+ unique wallets, representing 81% of all DEX users in the TON ecosystem.

25,800+ daily active users, with 16,000+ making multiple transactions daily.

8,000+ new users joining the platform daily, marking record-breaking adoption.

700+ trading pairs actively transacted every day.

And beyond the daily activity:

$425,000,000 – Average monthly trading volume in 2024.

$370,000,000 – Peak total value locked (TVL).

50x-80x increase in both trading volume and TVL over the past year.

$5.2 billion+ total trading volume to date.

20 million+ total transactions processed.

These aren’t just numbers; they are proof of STON.fi’s leadership, reliability, and adoption within the DeFi space.

The Future of Trading Starts Now

The integration of STON.fi and Wisdomise represents a major step forward for traders who seek automation, efficiency, and deeper market access. The power of AI-driven trading combined with the deep liquidity of STON.fi creates a smarter, more profitable trading experience.

🔗 Start trading now with STON.fi on Wisdomise and unlock a new level of DeFi trading!

4 notes

·

View notes

Text

Omniston on STONfi DEX: Simplifying DeFi for Everyone

The world of decentralized finance (DeFi) is constantly evolving, and with each advancement comes new opportunities to improve the way we trade and manage our assets. One such innovation is Omniston, a feature integrated into the STONfi DEX that aims to reshape how decentralized trading works. Let me walk you through this in the simplest way possible so you can see why this matters to you and the broader DeFi ecosystem.

What is Omniston, and Why Should You Care

Think of Omniston as a smart marketplace for crypto trading. Instead of relying on traditional liquidity pools, where your assets sit idle waiting for someone to trade against them, Omniston connects you directly with market makers.

Here’s a relatable analogy: imagine you want to buy a car. Instead of visiting multiple dealerships and negotiating prices, you post your desired car specifications and wait for sellers to offer their best deals. Once you pick the one that suits you, the transaction happens directly. That’s essentially how Omniston operates, using a Request for Quote (RFQ) system to ensure traders get the best offers for their swaps.

Why is Omniston Different

1. Full Control Over Your Funds

Imagine keeping your money in your wallet instead of handing it to someone else while waiting for a deal. With Omniston, you maintain complete control of your assets until the moment of the transaction. This eliminates the risk of someone mishandling or misusing your funds.

2. No Need to Trust Anyone

In the world of traditional trading, trust is a huge factor—you’re often required to trust platforms or third parties to handle your assets securely. With Omniston, trust isn’t necessary because everything is governed by smart contracts. These are automated agreements written into the blockchain that ensure the terms are met before the transaction happens. It’s like having a foolproof contract that executes itself without bias.

3. Crystal-Clear Pricing

If you’ve ever been surprised by hidden fees or unexpected costs, you’ll appreciate Omniston’s transparency. When you use the RFQ system, you know exactly how much you’re paying and receiving before confirming the trade. No hidden charges, no unpleasant surprises—just straightforward trading.

How Does Omniston Enhance STONfi DEX

STONfi DEX has already earned a reputation for its user-friendly approach to decentralized trading. Adding Omniston only strengthens its position as a leading platform in the DeFi space.

Unified Liquidity: Rather than fragmenting liquidity across various platforms, Omniston brings it all together in one place. This makes trading more efficient and provides access to a broader range of tokens.

Speed and Efficiency: By combining off-chain order processing with on-chain settlements, Omniston ensures faster and cheaper transactions. This dual approach eliminates unnecessary delays and hefty fees often associated with other platforms.

Better Ecosystem Access: Developers and traders alike benefit from Omniston’s integration. It opens up opportunities to connect with millions of users and projects within the TON Space ecosystem, creating a thriving network of possibilities.

Why Unified Liquidity Matters

To understand the importance of unified liquidity, let’s consider another analogy. Think of liquidity as water. If you have a small amount scattered across several cups, it’s not very useful. But if you pour all the water into one large container, you have a more practical resource.

Omniston applies this principle to trading by pooling liquidity into a single platform. This means traders can access better prices and larger volumes, while projects benefit from increased visibility and participation.

Why This Innovation Matters

At its core, Omniston addresses some of the most persistent challenges in DeFi—security, transparency, and accessibility. By leveraging smart contracts and the RFQ system, it ensures that users have a seamless experience without compromising on safety or control.

For experienced traders, this means better prices and faster trades. For newcomers, it simplifies the process, making DeFi less intimidating and more approachable. And for the DeFi ecosystem as a whole, it sets a new standard for how decentralized trading should work.

The Bigger Picture

Omniston isn’t just a feature; it’s a step toward creating a more unified and user-friendly DeFi landscape. Its integration with STONfi DEX demonstrates the platform’s commitment to innovation and user-centric solutions.

Whether you’re a seasoned trader looking for efficiency or a beginner wanting to explore DeFi without unnecessary risks, Omniston offers a solution that feels intuitive and reliable. It’s more than just technology—it’s a practical tool designed with real users in mind.

Final Thoughts

In a space as dynamic as DeFi, advancements like Omniston remind us why decentralization matters. It’s about giving power back to the users, ensuring security without compromise, and making financial systems accessible to everyone.

As someone deeply invested in this ecosystem, I believe Omniston on STONfi DEX is a game-changer. It simplifies the complex, removes unnecessary barriers, and opens up opportunities for traders and developers alike. If you’ve been hesitant about diving into DeFi, now might be the perfect time to explore how innovations like this can make your journey smoother and more rewarding.

What are your thoughts on Omniston? Let’s discuss!

3 notes

·

View notes

Text

The Importance of Steel Factory in Modern Industry

Steel Factory play a pivotal role in modern infrastructure and industrial development. As the backbone of construction, manufacturing, transportation, and various other sectors, steel production is essential to creating the durable materials that shape our daily lives. From skyscrapers to automobiles, bridges to household appliances, steel is an indispensable resource that drives economic growth and innovation.

What is a Steel Factory?

A steel factory, also known as a steel mill, is a facility where raw materials such as iron ore, coal, and limestone are transformed into steel. These factories are responsible for producing different types of steel, each with varying characteristics and properties depending on its intended use. Steel factories utilize a combination of processes, including melting, casting, rolling, and shaping, to produce steel in the form of sheets, bars, coils, or beams.

There are two primary types of steel mills:

Integrated Steel Mills: These plants handle the entire production process, from refining raw materials to producing finished steel.

Mini Mills: These focus on recycling scrap steel and refining it into new steel products, contributing to sustainable manufacturing practices.

The Steel Production Process

The production of Steel Factory involves several key steps. The most common method is the Basic Oxygen Furnace (BOF) process, while the Electric Arc Furnace (EAF) method is used in mini mills for recycling scrap metal.

Ironmaking: The first step involves extracting iron from iron ore in a blast furnace. The furnace heats the ore along with coke (a carbon-rich substance derived from coal) and limestone, producing molten iron and slag (a by-product used in other industries).

Steelmaking: In the steelmaking phase, molten iron is combined with scrap metal and oxygen to reduce carbon content and impurities. This process, typically done in a basic oxygen furnace, creates liquid steel.

Casting: The liquid steel is then poured into molds to create solid shapes, which can include slabs, billets, and blooms. These are the raw forms of steel that will be further processed.

Rolling and Shaping: After cooling, the steel is rolled into thinner sheets or shaped into desired forms, such as bars or beams. These products are then ready for industrial use.

Finishing: Depending on the intended use of the steel, additional processes such as heat treatment, coating, or surface treatments may be applied to enhance durability, corrosion resistance, and aesthetic appeal.

The Role of Steel Factories in Infrastructure

Steel is a foundational material in modern infrastructure. Steel Factory supply the structural components needed for building everything from bridges to high-rise buildings. Steel’s strength, flexibility, and resilience make it the ideal material for supporting heavy loads and withstanding environmental stressors.

Construction: Steel beams, girders, and rebar are essential components in large-scale construction projects, providing stability to buildings and bridges.

Transportation: Steel factories produce materials for the automotive, shipbuilding, and railway industries. From the frames of vehicles to the tracks that trains run on, steel is integral to modern transportation systems.

Energy: Steel is used in the construction of oil rigs, wind turbines, and pipelines, playing a crucial role in energy infrastructure.

Steel Factories and Sustainability

As concerns about climate change and environmental degradation grow, steel factories are making significant strides toward sustainability. Many steel producers are shifting towards eco-friendly methods, such as using Electric Arc Furnaces to recycle scrap metal and adopting cleaner technologies that reduce emissions.

Innovations in Steel Manufacturing

Steel Factory are at the forefront of technological innovation. Advances in automation, artificial intelligence, and robotics have transformed the industry, increasing efficiency and reducing costs. Some key innovations include:

High-Strength Steel: New steel alloys are being developed that offer higher strength while using less material, making them more environmentally friendly and cost-effective.

3D Printing with Steel: The rise of additive manufacturing has introduced the possibility of 3D printing with steel, which could revolutionize industries such as aerospace and automotive engineering.

Smart Factories: The integration of IoT (Internet of Things) devices allows for better monitoring of equipment and processes in steel mills, optimizing production and minimizing downtime.

Conclusion

Steel Factory are the cornerstone of industrial progress. They provide the raw materials necessary for countless industries, from construction to transportation and energy. As technological advancements and environmental concerns shape the future of steel production, these factories continue to adapt and innovate, ensuring that steel remains a vital part of modern life.

The next time you see a skyscraper, drive a car, or walk across a bridge, remember that it all started in a steel factory—a place where raw materials are transformed into the building blocks of our world.

Metal Berg Manufacturing Company Factory

Block 16 Plot 283, Green Estate, Amuwo Odofin Estate 102102, Lagos, Nigeria

+234 803 044 2676

2 notes

·

View notes

Text

Maximize Efficiency with Expert Cash Management Solutions

In today’s fast-paced business environment, effective cash management is crucial for maintaining financial stability and supporting growth. Expert cash management solutions can help businesses streamline their operations, optimize liquidity, and enhance overall financial efficiency. This article explores how leveraging advanced cash management solutions can maximize efficiency and drive business success.

What is Cash Management?

Cash management involves the collection, handling, and use of cash in a business. The goal is to ensure that a company has enough cash on hand to meet its short-term obligations while optimizing the use of its funds. Effective cash management helps businesses avoid liquidity problems, reduce financing costs, and invest surplus cash wisely.

Key Benefits of Expert Cash Management Solutions

Improved Cash Flow Visibility

Expert cash management solutions provide real-time insights into cash flow. By integrating these solutions with your financial systems, you can gain a comprehensive view of your cash position, including incoming and outgoing funds. This visibility allows for better forecasting and planning, helping you anticipate cash needs and avoid potential shortfalls.

Enhanced Liquidity Management

Managing liquidity effectively is essential for ensuring that your business can meet its obligations without holding excessive cash. Advanced cash management tools help optimize liquidity by analyzing cash flow patterns and recommending strategies to manage working capital more efficiently. This includes managing accounts receivable and payable, optimizing cash reserves, and reducing idle cash.

Streamlined Cash Collection and Disbursement

Automated cash management solutions streamline the collection and disbursement processes. For example, electronic invoicing and payment systems can accelerate the receipt of payments, reducing the time it takes to convert receivables into cash. Similarly, automated disbursement systems help manage outgoing payments, ensuring that bills and payroll are processed efficiently and on time.

Enhanced Fraud Prevention and Security

Security is a critical aspect of cash management. Expert solutions offer robust security features to protect against fraud and unauthorized transactions. This includes encryption, multi-factor authentication, and transaction monitoring. By implementing these security measures, businesses can safeguard their cash and reduce the risk of financial losses due to fraud.

Optimized Investment Opportunities

Efficient cash management doesn’t just involve managing daily transactions; it also includes investing surplus cash to generate returns. Expert cash management solutions help identify and evaluate investment opportunities that align with your company’s risk tolerance and financial goals. Whether it’s investing in short-term instruments or managing liquidity portfolios, these solutions provide insights to make informed investment decisions.

Regulatory Compliance

Adhering to regulatory requirements is essential for avoiding penalties and maintaining financial integrity. Advanced cash management systems help ensure compliance with relevant regulations by automating reporting and record-keeping. This includes managing tax-related cash flows, regulatory filings, and maintaining accurate financial records.

Implementing Expert Cash Management Solutions

To maximize efficiency with expert cash management solutions, consider the following steps:

Assess Your Needs

Begin by evaluating your business’s cash management needs. Identify areas where improvements are needed, such as cash flow forecasting, liquidity management, or fraud prevention. This assessment will help you choose the right solutions that align with your business objectives.

Choose the Right Tools

Select cash management solutions that offer the features and functionality you need. Look for tools that integrate with your existing financial systems, provide real-time insights, and offer robust security measures. Consider solutions that are scalable and can grow with your business.

Implement and Integrate

Once you’ve selected the appropriate solutions, implement them within your organization. This may involve integrating the solutions with your current financial systems, training staff on how to use the tools, and establishing processes for managing cash flow effectively.

Monitor and Optimize

Regularly monitor the performance of your cash management solutions to ensure they are delivering the expected benefits. Use the insights provided by these tools to make data-driven decisions, optimize cash flow, and adjust your strategies as needed.

Review and Adjust

Periodically review your cash management practices and solutions to ensure they remain effective. As your business evolves, your cash management needs may change, requiring adjustments to your strategies and tools.

Conclusion

Expert cash management solutions are essential for maximizing efficiency and achieving financial stability in today’s competitive business landscape. By leveraging advanced tools and strategies, businesses can gain better visibility into their cash flow, optimize liquidity, streamline processes, and enhance security. Implementing these solutions helps ensure that your business can meet its financial obligations, invest wisely, and maintain a strong financial position. Embracing expert cash management practices not only improves day-to-day operations but also supports long-term growth and success.

For more details, visit us:

expense tracker software

Expense Management Software

invoice management system

best expense reimbursement software

3 notes

·

View notes

Text

Liquid Handling in Drug Discovery: Enhancing Precision and Throughput

Liquid handling is a critical process in drug discovery, involving the accurate and efficient transfer of liquids between containers. The precision and throughput of liquid handling operations can significantly impact the success of drug discovery research. In this blog post, we will explore the importance of precision liquid handling in drug discovery and discuss some of the key technologies and techniques that are used to enhance precision and throughput.

The Importance of Liquid Handling in Drug Discovery

Liquid handling is a fundamental aspect of drug discovery research, with applications ranging from compound screening and formulation to analysis and quality control. Accurate and precise liquid handling is essential for:

Ensuring data reliability: Inconsistent liquid handling can lead to errors in experimental data, compromising the validity of research findings.

Improving efficiency: Efficient liquid handling techniques can accelerate the drug discovery process and reduce costs.

Enhancing reproducibility: Consistent liquid handling practices are crucial for ensuring reproducibility of experimental results.

Liquid Handling Technologies

A variety of liquid handling systems are available to researchers, each with its own advantages and limitations. Some of the most commonly used technologies include:

Manual pipettes: While still widely used, manual pipettes can be time-consuming and prone to human error.

Electronic pipettes: Automated pipetting systems offer improved accuracy and precision compared to manual pipettes, as well as features such as adjustable pipetting speeds and programmable protocols.

Liquid handling workstations: Automated liquid handling workstations can significantly increase throughput and reduce the risk of human error. These systems can be programmed to perform complex liquid handling tasks, such as serial dilutions, transfers, and aliquoting.

Techniques for Enhancing Precision and Throughput

In addition to selecting the appropriate liquid handling technology, researchers can also employ a number of techniques to enhance precision and throughput:

Tip calibration: Regular calibration of pipette tips is essential for ensuring accurate liquid handling.

Liquid handling robotics: Automated liquid handling robots can be used to perform repetitive tasks with high precision and speed.

Miniaturization: Reducing the volume of liquid handled can improve efficiency and reduce costs.

Microfluidics: Microfluidic devices can enable high-throughput liquid handling with minimal sample volumes.

Conclusion

Liquid handling is a critical process in drug discovery that requires precision, accuracy, and efficiency. By selecting the appropriate technologies and techniques, researchers can enhance the quality and speed of their work, ultimately accelerating the development of new drugs.

#precision liquid handling#liquid handling#liquid handling systems#Automated pipetting systems#pipette tips#pipettes#micropipette#pipette filler

0 notes

Text

What is a DC Load Bank?

In the world of electrical engineering and testing, the term "DC load bank" might not be one you encounter every day, but its importance is monumental, especially in industries relying on direct current (DC) power systems. This article will delve into what a DC load bank is, its applications, and why they are essential for ensuring the reliability and efficiency of power systems. Welcome to an exploration of the unsung hero in power testing—EMAX Load Bank's specialty.

Understanding DC Load Banks

A DC load bank is a device designed to simulate electrical loads on a power source, specifically one that provides direct current. This simulation is crucial for testing and validating the performance and reliability of DC power systems, such as batteries, power supplies, and photovoltaic (solar) systems. By applying a controlled load, a DC load bank helps in determining how well a power source can handle real-world conditions and perform under various scenarios.

Components of a DC Load Bank

A typical DC load bank comprises several key components:

Resistive Elements: These are the primary components that dissipate power in the form of heat. They simulate the electrical load.

Control Systems: These allow for the adjustment and regulation of the load applied to the power source. Advanced control systems enable precise load management.

Cooling Systems: Since resistive elements generate heat, efficient cooling mechanisms (fans or liquid cooling) are essential to maintain safe operating temperatures.

Measurement Instruments: These instruments monitor voltage, current, and other relevant parameters to provide accurate data during testing.

Applications of DC Load Banks

Battery Testing

Batteries are at the heart of many DC power systems, from small-scale applications like consumer electronics to large-scale uses such as backup power systems and electric vehicles. DC load banks are used to perform discharge testing on batteries, ensuring they can deliver the required power over their expected lifespan. This testing is crucial for identifying potential issues and ensuring reliability.

Power Supply Validation

Power supplies need to be reliable and efficient, especially in critical applications like data centers, telecommunications, and industrial automation. DC load banks test these power supplies under different loads to verify their performance, efficiency, and stability. This process helps in identifying any weaknesses that might lead to failures or inefficiencies in real-world conditions.

Renewable Energy Systems

With the rise of renewable energy, particularly solar power, ensuring the reliability and efficiency of photovoltaic systems is paramount. DC load banks test these systems by simulating various load conditions, helping in the optimization and verification of solar panels and their associated power electronics.

Electric Vehicle Testing

Electric vehicles (EVs) rely heavily on DC power systems for propulsion and auxiliary functions. DC load banks play a critical role in testing EV batteries and power electronics, ensuring they can meet the demanding conditions of real-world driving. This testing is essential for safety, performance, and the overall user experience of EVs.

Why DC Load Banks are Essential

Ensuring Reliability

The primary purpose of a DC load bank is to ensure the reliability of power systems. By simulating real-world conditions, these devices help identify potential issues before they cause failures. This proactive approach to testing can prevent costly downtime and improve the overall dependability of power systems.

Enhancing Efficiency

Efficiency is a key consideration in any power system. DC load banks help in optimizing the performance of power sources, ensuring they operate at peak efficiency under various conditions. This optimization can lead to significant cost savings over time, especially in large-scale applications like industrial plants or renewable energy farms.

Safety Assurance

Safety is paramount in any electrical system. DC load banks help in identifying and mitigating risks by testing power sources under controlled conditions. This testing can reveal potential safety issues, such as overheating or overloading, allowing for corrective measures to be taken before real-world deployment.

Supporting Innovation

As technology advances, so do the demands on power systems. DC load banks support innovation by providing a reliable means of testing new power sources and technologies. This support is crucial for the development of next-generation batteries, power supplies, and renewable energy systems.

EMAX Load Bank: Leading the Way

In the realm of DC load banks, EMAX Load Bank stands out as a leader, providing cutting-edge solutions for a wide range of applications. EMAX Load Bank's products are designed with precision and reliability in mind, ensuring that they meet the rigorous demands of modern power systems.

Advanced Features

EMAX Load Bank offers advanced features that set their products apart:

Precision Control: EMAX Load Bank's control systems allow for precise load management, ensuring accurate testing and validation.

Robust Construction: Built to withstand demanding conditions, EMAX Load Bank's products are durable and reliable.

Comprehensive Monitoring: With state-of-the-art measurement instruments, EMAX Load Bank provides comprehensive data for analysis and optimization.

Commitment to Quality

EMAX Load Bank is committed to quality and innovation, continuously improving their products to meet the evolving needs of the industry. Their dedication to excellence ensures that customers receive the best possible solutions for their testing and validation needs.

Conclusion

DC load banks are essential tools in the world of electrical engineering, providing critical support for the testing and validation of DC power systems. From battery testing to renewable energy systems, these devices play a vital role in ensuring reliability, efficiency, and safety. EMAX Load Bank, with its advanced features and commitment to quality, leads the way in providing top-notch DC load bank solutions.

As technology continues to advance and the demand for reliable power systems grows, the importance of DC load banks will only increase. Whether you're in the field of renewable energy, electric vehicles, or industrial power systems, understanding and utilizing DC load banks is key to ensuring success and innovation in your endeavors.

2 notes

·

View notes

Text

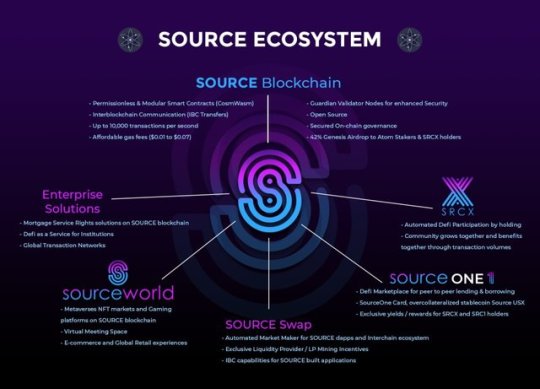

SOURCE PROTOCOL

SOURCE is building limitless enterprise applications on a secure and sustainable global network. Defi white-labelled services, NFT markets, RWA tokenization, play-to-earn gaming, Internet of Things, data management and more. SOURCE is providing blockchain solutions to the real world and leveraging the power of interoperability.

SOURCE competitive advantages over other blockchain projects

For builders & developers — Source Chain’s extremely high speeds (2500–10000+ tx / per second), low cost / gas fees ($0.01 average per tx), and scalability (developers can deploy apps in multiple coding languages using CosmWasm smart contract framework), set it apart as a blockchain built to handle mass adopted applications and tools. Not to mention, it’s interoperable with the entire Cosmos ecosystem.

For users — Source Protocol’s DeFi suite is Solvent and Sustainable (Automated liquidity mechanisms create a continuously self-funded, solvent and liquid network), Reduces Complexity (we’re making Web 3.0 easy to use with tools like Source Token which automate DeFi market rewards), and we’ve implemented Enhanced Security and Governance systems (like Guardian Nodes), which help us track malicious attacks and proposals to create a safer user environment.

For Enterprises — Source Protocol is one of the first to introduce DeFi-as-a-Service (DaaS) in order for existing online banking and fintech solutions to adopt blockchain technology with ease, and source also provides Enterprise Programs which are complete with a partner network of OTC brokerages, crypto exchanges, and neobanks that create a seamless corporate DeFi experience (fiat onboarding, offboarding, and mutli-sig managed wallets)

Why Source Protocol

Firstly, many protocols are reliant on centralized exchanges for liquidity, limiting their ability to scale independently. This creates a lot of the same issues traditional finance has been plagued with for decades.

Next — slow tx speeds, high costs, limited scalability, and inability to collaborate with other chains, has created severe limitations in Gen 2 blockchain infrastructure.

Lastly, there still exists a level of complexity in blockchain applications that remains a barrier to entry for the average user, and there is not enough focus on building “bridges” for the enterprise to adopt this technology easily and quickly.

In summary, consumers are eager for a blockchain ecosystem that can securely and sustainably support mass adopted applications. That’s why we’ve built Source!

Source Protocol’s ecosystem

Source Protocol’s ecosystem includes a full DeFi Suite, a members rewards program and white-label integration capabilities with existing online Web 2.0 enterprises:

Source Swap — An Interchain DEX & AMM built on Source Chain for permission-less listing of $SOURCE-based tokens, native Cosmos SDK assets, cw-20’s, and wrapped Binance Smart Chain (BEP-20) assets.

Source One Market — A peer to peer, non-custodial DeFi marketplace for borrowing, lending, staking, and more. Built on Binance Smart Chain with bridging to Source Chain & native Cosmos SDK assets.

Source Token $SRCX (BEP-20) — the first automated liquidity acquisition and DeFi market participation token built on Binance Smart Chain.

Source One Token $SRC1 (BEP-20) — a governance and incentivized earnings token that powers Source One Market.

Source USX $USX (BEP-20) — Source One Market stablecoin backed and over collateralized by a hierarchy of blue chip crypto assets and stablecoins.

Source Launch Pad — Empowering projects to seamlessly distribute tokens and raise liquidity. ERC-20 and BEP-20 capable.

Source One Card & Members Rewards Program — users can earn from a robust suite of perks and rewards. In the future, Source One Card will enable users to swipe with their crypto assets online and at retail locations in real time.

DeFi-as-a-Service (DaaS) — Seamless white-label integration of Source One Market, Source Swap, Source Launch Pad, and/or Source One Card with existing online banking and financial applications, allowing businesses to bring their customers DeFi capabilities.

Source Protocol Key Components

Sustainable Growth model built for enterprise involvement and mass application adoption

Guardian Validator Nodes for enhanced network security

Integration with Source Protocol’s Binance Smart Chain Ecosystem and Decentralized Money Market, Source One Market

Source-Drop (Fair community airdrop and asset distribution for ATOM stakers and SRCX holders)

Interoperable smart contracts (IBC)

High speed transaction finality

Affordable gas fees (average of $0.01 per transaction)

Highly scalable infrastructure

Open-source

Permission-less Modular Wasm + (EVM)

Secured on-chain governance

Ease of use for developers

conclusion

SOURCE is a comprehensive blockchain technology suite for individuals, enterprises and developers to easily use, integrate and build web3.0 applications. It is a broad-spectrum technology ecosystem that transforms centralized web tools and financial instruments into decentralized ones. Powering the future of web3,

Next — slow tx speeds, high costs, limited scalability, and inability to collaborate with other chains, has created severe limitations in Gen 2 blockchain infrastructure.

Lastly, there still exists a level of complexity in blockchain applications that remains a barrier to entry for the average user, and there is not enough focus on building “bridges” for the enterprise to adopt this technology easily and quickly.

In summary, consumers are eager for a blockchain ecosystem that can securely and sustainably support mass adopted applications. That’s why we’ve built Source!

For More Information about Source Protocol

Website: https://www.sourceprotocol.io

Documents: https://docs.sourceprotocol.io

Twitter: https://www.twitter.com/sourceprotocol_

Instagram: https://www.instagram.com/sourceprotocol

Telegram: https://t.me/sourceprotocol

Discord: https://discord.gg/zj8xxUCeZQ

Author

Forum Username: Java22

Forum Profile Link: https://bitcointalk.org/index.php?action=profile;u=3443255

SOURCE Wallet Address: source1svnzfy5fafuskeaxmf2sgvgcn6k3sggmssl8d7

2 notes

·

View notes

Text

Maximizing Efficiency: Best Practices for Using Sequencing Consumables

By implementing these best practices, researchers can streamline sequencing workflows, increase throughput, and achieve more consistent and reproducible results in genetic research. Sequencing Consumables play a crucial role in genetic research, facilitating the preparation, sequencing, and analysis of DNA samples. To achieve optimal results and maximize efficiency in sequencing workflows, it's essential to implement best practices for using these consumables effectively.

Proper planning and organization are essential for maximizing efficiency when using Sequencing Consumables. Before starting a sequencing experiment, take the time to carefully plan out the workflow, including sample preparation, library construction, sequencing runs, and data analysis. Ensure that all necessary consumables, reagents, and equipment are readily available and properly labeled to minimize disruptions and delays during the experiment.

Optimizing sample preparation workflows is critical for maximizing efficiency in sequencing experiments. When working with Sequencing Consumables for sample preparation, follow manufacturer protocols and recommendations closely to ensure consistent and reproducible results. Use high-quality consumables and reagents, and perform regular quality control checks to monitor the performance of the workflow and identify any potential issues early on.

Utilizing automation technologies can significantly increase efficiency when working with Sequencing Consumables. Automated sample preparation systems and liquid handling robots can streamline repetitive tasks, reduce human error, and increase throughput. By automating sample processing and library construction workflows, researchers can save time and resources while improving consistency and reproducibility in sequencing experiments.

Get More Insights On This Topic: Sequencing Consumables

#Sequencing Consumables#DNA Sequencing#Laboratory Supplies#Genetic Analysis#Next-Generation Sequencing#Molecular Biology#Research Tools#Bioinformatics

2 notes

·

View notes

Text

How Rightpath GS Enhances Accounts Payable Services for Smarter Financial Management

Efficient financial operations are the backbone of any successful business. However, manual and outdated processes often lead to delays, errors, and compliance risks. This is why companies today are turning to specialists like Rightpath GS for accounts payable services that are accurate, scalable, and cost-effective. As a leader in finance and accounting outsourcing, Rightpath GS helps businesses simplify their payables and improve overall cash flow.

Outsourcing your payables isn’t just about saving time—it’s about gaining control over your financial processes. Rightpath GS offers comprehensive accounts payable outsourcing solutions that handle everything from invoice capture and approvals to payment processing and vendor reconciliation. With built-in compliance checks and automation tools, they ensure your accounts are always audit-ready and error-free. Their accounts payable outsourcing companies model integrates seamlessly with client systems, maintaining transparency and giving real-time access to financial data.

What sets Rightpath GS apart is their end-to-end approach. They don’t just process invoices—they optimize the entire BPO accounting process. By analyzing invoice trends, identifying cost-saving opportunities, and eliminating duplicate or fraudulent entries, they ensure your finance team can focus on strategic decisions instead of day-to-day clerical tasks. Their team ensures a smooth workflow that matches your internal policies while enhancing operational speed.

Beyond payables, Rightpath GS also extends support across multiple finance functions. Their services include accounts receivable outsourcing, General Ledger services, and financial planning and analysis—giving clients a 360-degree solution for all accounting needs. Businesses can also choose to outsource receivables alongside payables to maintain a balanced and healthy cash flow. With this approach, companies gain improved liquidity, reduced processing costs, and better credit control.

0 notes

Text

Top Packaging Machine Manufacturers in India: Discover NPM Machinery’s Innovation in Automation

In today’s competitive manufacturing landscape, packaging is not just about wrapping products—it’s a critical process that ensures product integrity, safety, regulatory compliance, and brand presentation. Whether it’s the pharmaceutical industry, personal care, agrochemical, food and beverage, or home care segments, efficient packaging plays a central role in successful product delivery. This rising demand has made it essential for businesses to partner with the right packaging machine manufacturers in India who can deliver precision, automation, and customization.

One such trusted and leading name is NPM Machinery. With a legacy of innovation, technical excellence, and industry-specific solutions, NPM Machinery is redefining how businesses automate their packaging processes across India and abroad.

Why Choose NPM Machinery?

NPM Machinery stands out among packaging machine manufacturers in India for offering a wide array of automation systems that are built for performance, durability, and accuracy. With a product range catering to every stage of the packaging process, NPM provides turnkey solutions for small-scale units as well as high-output manufacturing plants.

Here are some of the key machine categories offered:

Washing and Air-Vacuum Cleaning Machines: These machines help maintain hygiene standards by thoroughly cleaning containers before filling.

Liquid and Powder Filling Machines: Ideal for dosing and dispensing liquids or powders with high precision and minimal wastage.

Tube Filling and Sealing Machines: Widely used in the pharma and cosmetic sectors, these machines handle viscous products like ointments and gels efficiently.

Visual Inspection Machines: Enable accurate product inspection under magnification to ensure quality compliance.

ROPP and Screw Capping Machines: Provide leak-proof, tamper-evident sealing of bottles and containers, crucial for product preservation.

Cartoning and Labeling Systems: Automate the end-of-line packaging with reliable and consistent box/carton sealing and label placement.

Each of these systems is developed using cutting-edge technology, ensuring consistent output, reduced labor dependency, and minimal downtime.

Built with Precision. Delivered with Commitment.

NPM Machinery emphasizes smart design, robust build quality, and simple user interfaces. Each product is engineered to offer high operational efficiency, reduce human error, and comply with regulatory norms. From design to assembly, every step is carried out at their in-house facility, ensuring full quality control.

Their machinery is designed to integrate easily into existing production lines and is suitable for operations of all sizes—from start-ups to established brands.

Made in India, Built for the World

With its firm alignment with the Make in India vision, NPM Machinery proudly manufactures its entire product portfolio locally, ensuring affordability, quick delivery, and technical support. Despite being based in India, NPM follows international standards like GMP, CGMP, and CE certifications—making its machines viable for use in global markets.

Their machines are already operating successfully in over 20 countries, including clients from Southeast Asia, the Middle East, Africa, and Europe, proving the trust and performance of Indian-made automation technology.

Custom Solutions and End-to-End Support

What makes NPM Machinery different from many packaging machine manufacturers in India is its end-to-end approach. They offer complete support that includes:

Pre-sales consultation for understanding client needs

Customized machine design as per production layout, material type, and filling accuracy

On-site installation, integration, and commissioning

Operator training to ensure safe and efficient usage

Post-sales support, maintenance, and remote troubleshooting

This consultative and personalized approach ensures that clients receive a solution—not just a machine—that aligns with their business goals.

Industry Applications

NPM Machinery caters to a wide spectrum of industries, including:

Pharmaceuticals – Tablet, capsule, liquid and ointment packaging

Nutraceuticals – Powder, syrup, and effervescent tablet packaging

Food & Beverages – Bottle filling, capping, labeling, and carton packing

Cosmetics & Personal Care – Tube filling, labeling, and inspection

Agrochemicals and Pesticides – Safe packaging of hazardous liquids and powders

Liquor and Wine – Sealing and bottling of glass containers

Every industry has its own regulatory and production requirements, and NPM ensures each machine is tailored accordingly.

✅ Call to Action

Looking for high-performance packaging solutions that improve production speed, meet compliance standards, and reduce costs?

👉 Explore NPM Machinery – Your Trusted Packaging Partner

#PackagingMachineManufacturersIndia#NPMPackagingSolutions#FillingMachinesIndia#AutomaticPackagingMachines#TubeFillingMachines#LiquidFillingMachines#VisualInspectionMachines#CartoningMachinesIndia#LabelingAndCappingMachines#MadeInIndiaMachinery#IndustrialPackagingSolutions#NPMLiquidFilling#AutomationIndia

0 notes

Text

How the Port of Jebel Ali Is Shaping the Future of Global Maritime Trade

In the ever-evolving world of maritime trade, ports play a critical role in connecting global economies. Among the most influential and strategically positioned ports in the world is the Port of Jebel Ali, located in the United Arab Emirates. Recognized as the largest man-made harbor and the busiest port in the Middle East, Jebel Ali serves as a crucial gateway for trade between Asia, Europe, and Africa. Its advanced infrastructure, logistical connectivity, and proximity to major markets make it a cornerstone in international shipping operations.

A Global Maritime Powerhouse

Since its inauguration in 1979, the Port of Jebel Ali has grown exponentially, becoming one of the world’s top ten container ports. Operated by DP World, the port spans over 134 square kilometers and is equipped with some of the most sophisticated container handling equipment in the industry. Its capability to handle ultra-large container vessels (ULCVs) has made it a preferred hub for leading shipping lines.

With annual throughput exceeding 13 million TEUs (twenty-foot equivalent units), the port facilitates the seamless movement of goods to and from over 150 ports worldwide. As global trade volumes continue to rise, the Port of Jebel Ali remains at the forefront of innovation and efficiency in maritime logistics.

To learn more about the port's specifications, services, and location, visit the Port of Jebel Ali information page.

Key Infrastructure and Capabilities

The Port of Jebel Ali offers world-class facilities that cater to a broad range of cargo types:

Container Terminals: The port features multiple terminals with over 70 berths and a total quay length exceeding 10,000 meters. These terminals are supported by advanced crane systems and automated yard operations, reducing dwell times and increasing throughput efficiency.

Ro-Ro and Bulk Cargo Handling: Aside from containers, the port is equipped to handle roll-on/roll-off (Ro-Ro) shipments and dry and liquid bulk cargo, supporting industries like automotive, construction, and energy.

Free Trade Zone Integration: Adjacent to the port is the Jebel Ali Free Zone (JAFZA), a 57-square-kilometer economic zone that allows businesses to operate with zero customs duties, 100% foreign ownership, and simplified licensing processes. This unique setup fosters seamless trade flow between port operations and industrial activities.

Digital Port Ecosystem: DP World has implemented several digital initiatives such as Cargoes Flow and smart trade platforms that automate and digitize customs, documentation, and cargo tracking.

Strategic Location and Connectivity

Geographically, Jebel Ali is positioned at the crossroads of major international shipping routes, making it a vital node in East-West trade. The port lies 35 kilometers southwest of Dubai, offering direct access to key regional and global markets.

Additionally, the port is integrated with Dubai International Airport and Al Maktoum International Airport via the Dubai Logistics Corridor, enabling multimodal transport and faster cargo handling. This multi-layered connectivity helps reduce transit times and logistics costs for shippers.

Sustainability and Innovation Initiatives

In response to increasing environmental concerns, the Port of Jebel Ali has embraced sustainability and green port practices. Initiatives include:

Electrification of port equipment

Use of solar panels for power generation

Advanced waste and water management systems

Real-time emissions monitoring

These measures align with the UAE’s long-term vision for sustainable development and further enhance the port’s reputation as a future-ready trade hub.

Port of Jebel Ali and the Supply Chain Resilience

In recent years, global supply chains have faced numerous disruptions—from pandemics to geopolitical tensions. Amid these challenges, the Port of Jebel Ali has demonstrated remarkable resilience, playing a pivotal role in rerouting and stabilizing trade flows.

The port’s ability to scale operations, adapt quickly to demand fluctuations, and offer alternative logistics solutions has been a lifeline for businesses seeking supply chain continuity.

If you're planning international freight movements or seeking a dependable port partner in the Middle East, the Port of Jebel Ali offers unmatched advantages in reliability, scalability, and connectivity.

Future Expansion and Smart Port Vision

Looking ahead, DP World is investing billions in expanding the port’s capacity and capabilities. Some of the key upcoming developments include:

Additional container berths to support future trade volumes

Implementation of AI-driven logistics platforms

Enhanced rail freight infrastructure to support inland connectivity

These initiatives are part of a broader strategy to transform Jebel Ali into a smart port, leveraging IoT, blockchain, and data analytics to provide predictive cargo tracking and improve decision-making.

Why Businesses Choose the Port of Jebel Ali

Several factors make Jebel Ali the port of choice for international businesses and freight forwarders:

Efficiency: Industry-leading turnaround times and minimal bottlenecks

Global Reach: Connectivity to 150+ global ports

Economic Zone Proximity: Integrated access to JAFZA

Regulatory Ease: Transparent customs and trade facilitation

Innovation: Commitment to digital transformation and sustainability

Whether you are in manufacturing, retail, automotive, or energy, the Port of Jebel Ali is equipped to meet your shipping and supply chain needs with professionalism and precision.

Conclusion

The Port of Jebel Ali is more than just a maritime facility—it's a dynamic engine powering international commerce. Its advanced infrastructure, strategic location, and forward-thinking approach make it a benchmark for modern port operations.

For businesses looking to optimize their global shipping routes and reduce logistical complexities, Jebel Ali offers a compelling proposition. Explore more about this critical port and its capabilities by visiting the dedicated port page.

Let me know if you'd like a shorter version, a PDF format, or content rewritten for another port or region.

1 note

·

View note